Digitalisation and automation are advancing inexorably. In Germany, more and more companies are relying on autonomous robot technologies to optimise their processes and meet the requirements of a modern, efficient industry. These technologies are playing an increasingly important role in the areas of logistics, production and safety in particular. Leading companies are already integrating advanced autonomous systems into their workflows and testing their potential. Which current developments are increasing the willingness to innovate and why now is the right time to utilise such technologies?

Growing readiness for autonomous technologies

The willingness to invest in autonomous robot technology is greater today than ever before. Various factors are contributing to this development::

- Labour shortage: In many industries, particularly in logistics, production and security, there is a significant shortage of qualified workers. Robots can serve not only as a supplement, but also as a replacement for certain repetitive or dangerous tasks. According to CoESS, 95% of security service providers have difficulties filling vacancies.

- Cost efficiency: The use of robots can reduce operating costs in the long term. Despite the high initial investment, robots offer an attractive cost-benefit balance due to higher efficiency, lower error rates and minimised downtime, which can also be easily scaled. Potential savings range from 17% to 45%, depending on the application, task definition, robot model, specifications, etc.

- Technological advances: Recent developments in robotics and artificial intelligence have led to autonomous systems becoming increasingly powerful and versatile. Robots are now able to perform complex tasks that were unthinkable just a few years ago.

- Safety concerns: Robots offer considerable advantages, particularly in safety-relevant areas such as infrastructure inspection or the monitoring of critical facilities. They can operate in hazardous environments and protect people from risks.

Leading companies are pioneers in the use of robotics

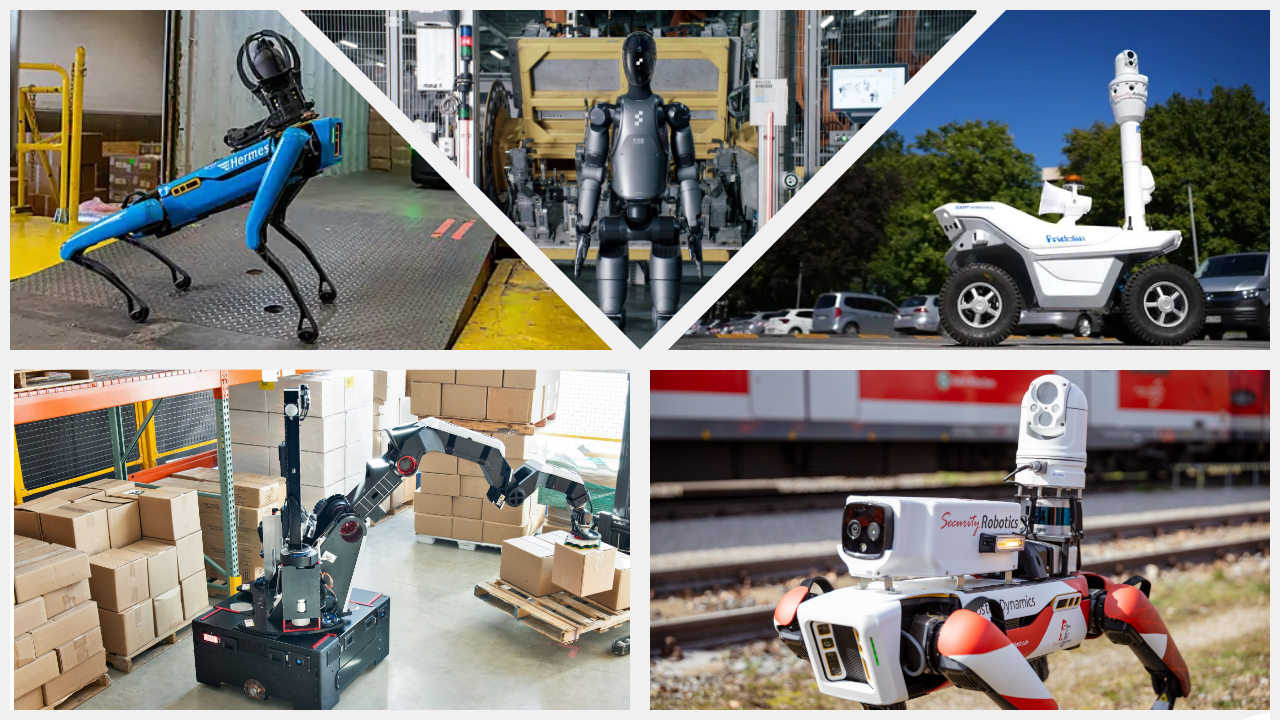

Hermes: Spot and Stretch in logistics

Hermes, one of the leading logistics companies in Germany, relies on robot technology from Boston Dynamics, in particular the Spot robot dog and the Stretch robot. Spot is used for inspections and security tasks in logistics centres. Stretch, a robotic arm specially developed for moving parcels, optimises efficiency in sorting and handling shipments. Both robots support Hermes in mastering the growing challenges in e-commerce and the logistics industry.

>> More Information: Bild Artikel über Hermes und Spot

Deutsche Bahn: Spot in action against graffiti

Deutsche Bahn has also integrated the Spot robot dog from Boston Dynamics into its processes. The robot is being tested at the Munich S-Bahn in particular to reduce graffiti damage and increase safety at railway stations. Spot can help to monitor areas that are difficult to access and detect damage at an early stage, which reduces maintenance work and the associated costs.

>> More Information: Deutsche Bahn über den Einsatz von Spot

BMW: Figure One in vehicle production

BMW relies on humanoid robot technologies to further optimise its production processes. The ‘Figure One’ robot is currently being tested in vehicle production. These robots are capable of carrying out complex assembly work that would otherwise require human dexterity. By integrating Figure One into production, BMW aims to increase the flexibility and efficiency of its production lines.

>> More Information: Heise Artikel über BMW und Figure One

DVV: Argus – the security guard on four wheels

Duisburger Versorgungs- und Verkehrsgesellschaft (DVV) is testing the use of the autonomous vehicle Argus to increase security on its premises. This robot autonomously monitors large areas and can recognise potential safety risks at an early stage. Particularly at night and in poor weather conditions, Argus ensures that safety on the premises is guaranteed at all times.

>> More Information: Kilometer 780 über Argus bei der DVV

BASF: Spot inspects water treatment plants

BASF, a leading global chemical company, relies on the Spot robot dog from Boston Dynamics at its water treatment plant in the port of Antwerp. Spot carries out routine inspections in the extensive plant, leading to a standardisation and increase in efficiency of the inspection processes. The robot, equipped with sensors and cameras, navigates autonomously through the plant, checks critical components and analyses the data using artificial intelligence. This enables precise monitoring, particularly in areas such as temperature control and the inspection of water basins. The use of Spot illustrates how BASF relies on technological innovation to maximise operational efficiency and ensure safety in critical infrastructure.

>> More Information: BASF Introduces Robot Dog ‘Spot’ for Water Treatment Facility Inspections

The most innovative sectors

The most innovative industries that currently rely on autonomous robot technology are:

- Logistics: Companies such as Hermes and the Otto Group are introducing autonomous robots for warehousing, sorting and delivery in order to keep pace with the growing demand in e-commerce.

- Automotive industry: Renowned manufacturers such as BMW use robots for quality control and production in order to increase efficiency and fulfil the highest precision requirements in complex assembly processes.

- Transport / traffic: Whether rail, ship or air traffic, a wide range of tasks involving service and safety issues can be digitalised, automated and also autonomously performed by robots on all routes, hubs and terminals, thereby optimising processes, reducing costs and protecting freight and people.

- Security: Multi-service providers, as well as small and large security companies in Germany, are increasingly relying on drone technology, patrol robots and multifunctional models that can perform a variety of tasks in parallel and significantly ease the precarious personnel situation in the security environment, while increasing the quality of the service.

- Industry 4.0: Companies such as Siemens are driving forward the integration of robots into networked production systems in order to maximise automation and optimise production processes.

- CRITIS: DVV is an ideal example of a modern approach to protecting critical infrastructures. Repetitive processes and dangerous tasks are outsourced to autonomous robots and their deployment profiles are constantly evaluated.

Summary and outlook

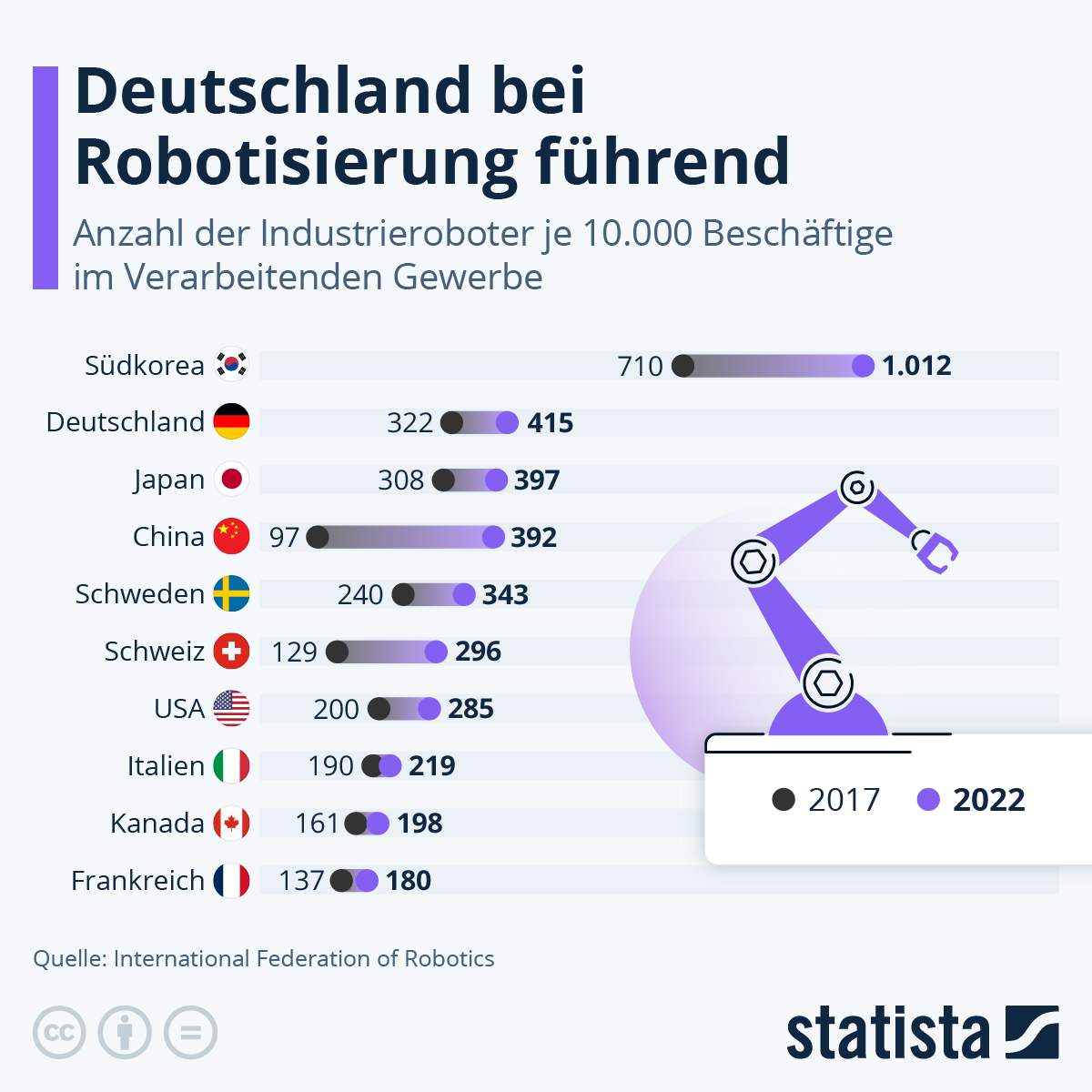

According to Statista, Germany ranked third worldwide in 2022 in terms of the use of industrial robotics in relation to the number of employees. However, robotics, especially under the growing influence of AI support, is no longer limited to manufacturing processes, but is increasingly finding its way into neighbouring industries such as logistics, transport and, of course, all safety-related topics. Well-known market leaders are already demonstrating how the integration of new walking, travelling and hovering robotic assistants can succeed in efficiently meeting current challenges.

>> More Information: Roboterdichte in der Fertigungsindustrie

In the coming years, we will see an even greater spread of these systems, particularly in areas where safety and precision are crucial. Companies that invest in these technologies at an early stage will secure a decisive competitive advantage and at the same time contribute to the further development of Industry 4.0.

CONTACT FOR PRESS & COMMUNICATION:

E-mail: info@security-robotics.de

Phone: +49 341 2569 3369