Open system robotics solutions at Security Robotics

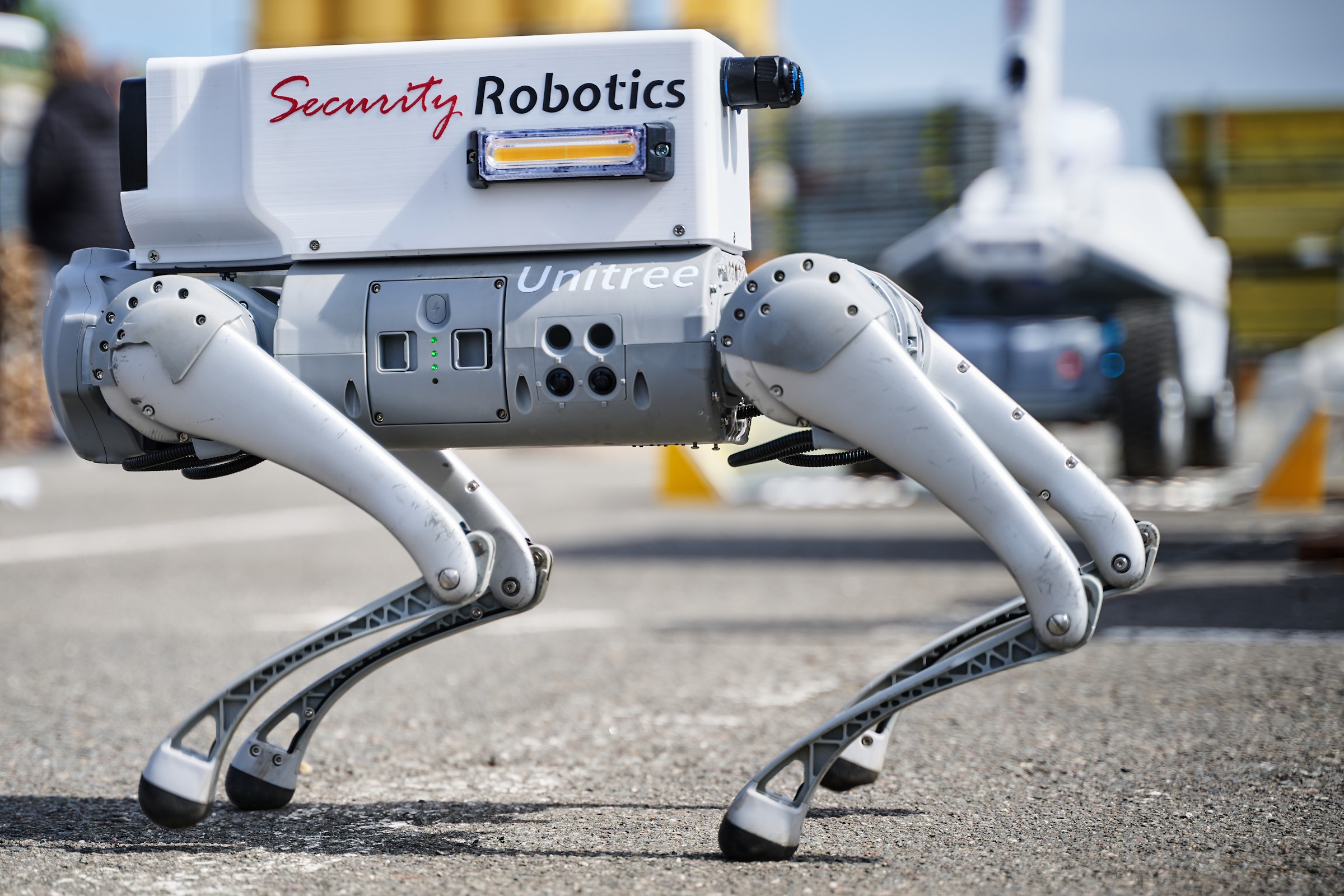

We offer tailor-made software solutions and specialize in the integration of robotic systems. We use hardware such as robots, drones, cameras and sensors, which are always the best platforms and devices for individual security concepts and customer requirements.

Innovation through partnerships

When selecting our suppliers and manufacturers, we look for a good mix of innovative strength, reliability and product maturity. This enables us to maintain long-term and sustainable partnerships. We work closely with leading robotics manufacturers, for some of whom we act exclusively as regional resellers and partners.

This regular dialog and the exchange of ideas from projects help us to drive forward the further development of safety robots and technologies. We integrate new functions and gain insights into new products at an early stage, which helps us to develop advanced solutions.

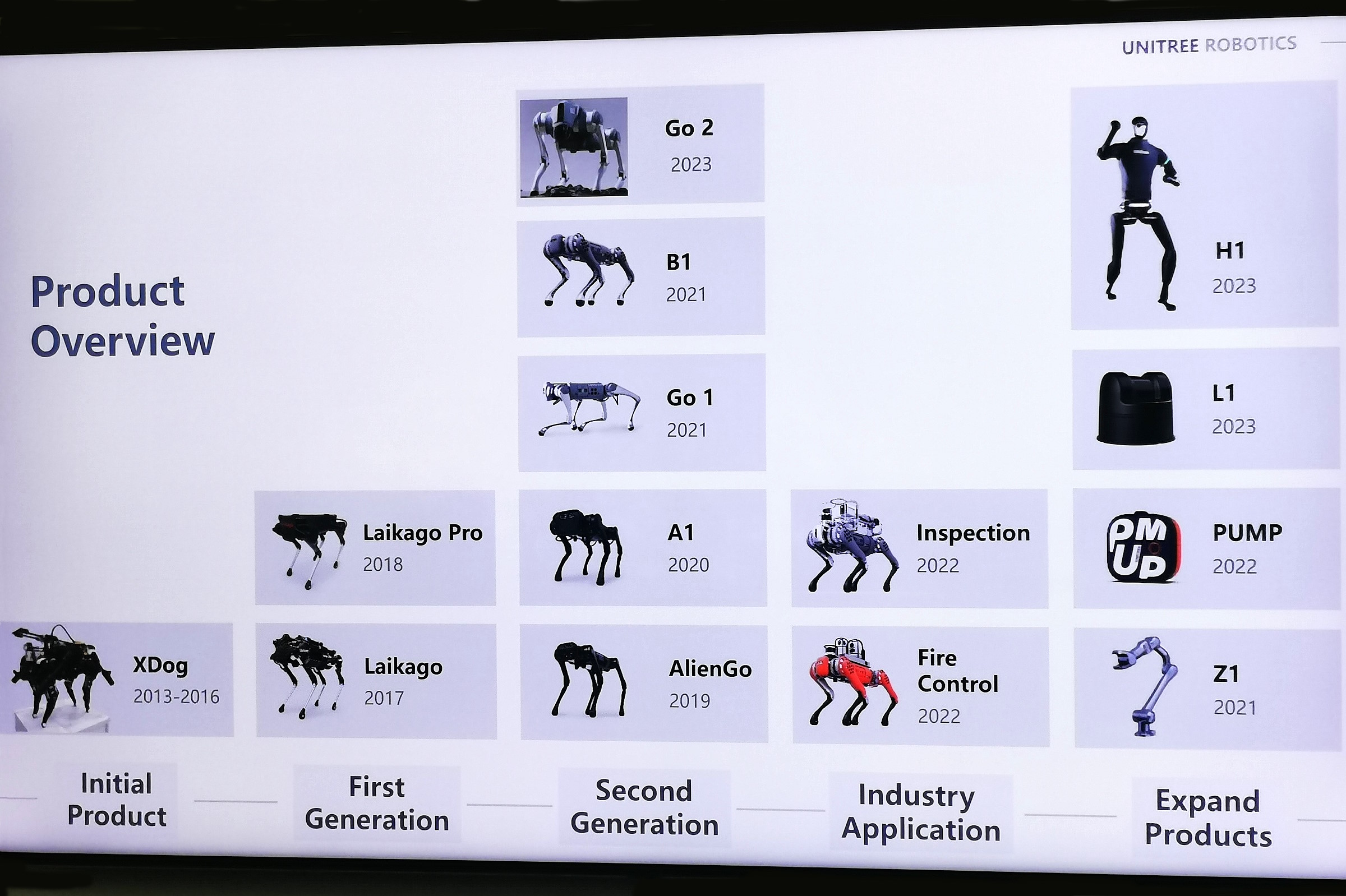

Unitree Robotics: A reliable partner

Unitree Robotics is one such partner. The company has been developing robots for over ten years and now also focuses on humanoid systems such as the G1. Unitree takes over all steps from research and development to production and sales, and can boast more than 180 patents of its own. With this experience and success, the company is well on the way to taking a leading role in robotics.

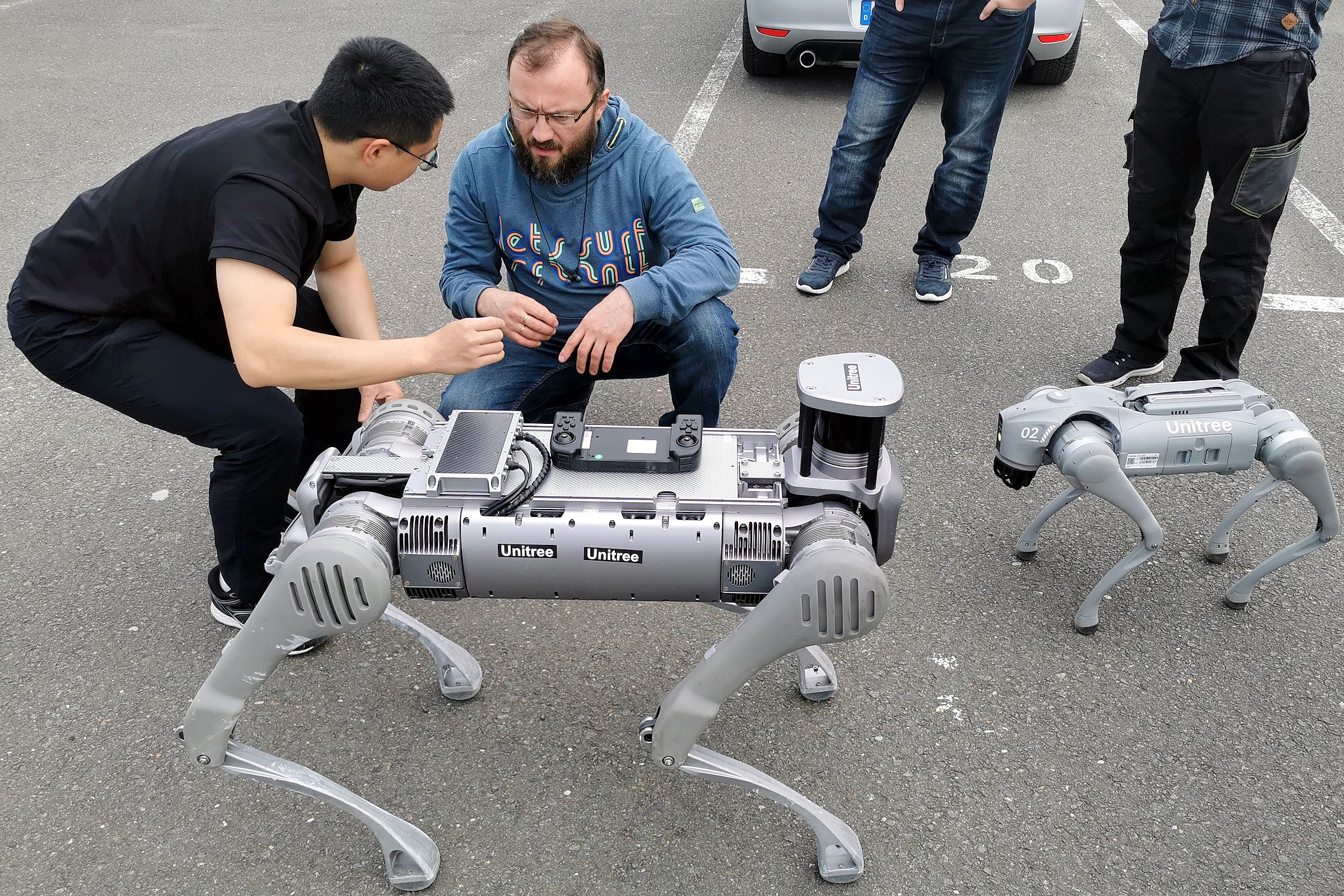

Naturally, we were eager to hear about the company’s latest developments. As soon as robotics experts from different cultures come together, a common understanding quickly prevails and possible language barriers fall away due to the enthusiasm for the technology.

Platform solutions: ACUDA and NUCRON

In our discussions with the partners, Mr. Zhang and Mr. Zheng, we discovered that Unitree Robotics operates purely as a hardware provider. Our responsibility lies in the integration and practical use of these systems in various applications. We rely on our own platform solution ACUDA (Autonomous Center of Unified Digital Actors), which connects IoT devices with robotics solutions. With the help of NUCRON, an IoT injector, we are expanding these systems with additional functions.

Careful testing for maximum reliability

Before new robots are added to our range, we test them thoroughly. We simulate real application scenarios on our test site to ensure that the robots work well. We test climbing ability, load-bearing capacity and robustness. The performance of the AI is also tested in various scenarios to guarantee reliability.

Go2: Progress in robotics

Another highlight was the Go2, the successor to the Go1. The Go2 weighs around 15 kg, reaches a speed of 5 m/s and is equipped with a lidar. With a load capacity of 8-12 kg and a battery life of up to 15,000 mAh, the Go2 offers numerous improvements compared to its predecessor. Of particular interest is its ability to patrol autonomously, which is made possible by a new charging station.

B2: Strength and versatility combined

The B2 impresses with its technical capabilities: It reaches a speed of over 6 m/s, can jump almost 2 m and has a load capacity of 40 kg. Its high climbing ability and weather resistance (IP67) make it ideal for outdoor use. Thanks to modern AI technology, the robot works reliably in different environments.

Expansion of our portfolio

Thanks to our system openness, we can compare different manufacturers and select the best system for each application. The new models from Unitreesuch as the Go2 and the B2, fit perfectly into our portfolio and offer an excellent extension to our security solutions.

Conclusion: The future of security robotics

Our partnerships and close cooperation with innovators such as Unitree Robotics enable us to offer safe solutions. Models such as the Go2 and the B2 show just how powerful modern robots can be. Through openness and regular exchange with our partners, we are constantly developing new technologies that are adapted to the requirements of our customers.

CONTACT FOR PRESS & COMMUNICATION:

E-mail: info@security-robotics.de

Phone: +49 341 2569 3369